and OTHER BAD OPTIONS

http://www.deepwaterhorizonresponse.com/go/doc/2931/532827/

http://www.deepwaterhorizonresponse.com/go/site/2931/

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/gulf_of_mexico_oil_spill_anima.html

OPEN CALL for BETTER IDEAS

(from DEEPWATER HORIZON UNIFIED COMMAND)

http://www.d8externalaffairs.com/go/doc/2931/542511/

“I have a technology, service, or idea to provide. How can I do that?

To submit an alternative technology, service or product, please contact (281) 366-5511. Submissions will be reviewed by appropriate experts.”

[youtube=http://www.youtube.com/watch?v=uxNkDyt6IjI]

1. CREATE a BURN ZONE

http://www.google.com/hostednews/afp/article/ALeqM5gV0p8P5QaVLyjmDfzlfO0W_59k9Q

Oil burn operation begins in Gulf of Mexico

by Allen Johnson

Emergency teams launched a “controlled burn” operation on Wednesday to stop a giant oil slick in the Gulf of Mexico from washing up on Louisiana’s ecologically fragile coast. A fleet of skimming vessels deployed by the US Coast Guard and British energy giant BP were sweeping the most dense concentrations of crude into a 500-foot (150-meter) fire resistant boom. “This oil will then be towed to a more remote area, where it will be ignited and burned in a controlled manner,” a joint statement said. The decision to burn the oil was taken after a slick with a 600-mile (965-kilometer) circumference spread within 23 miles of Louisiana’s wetlands, which are an important sanctuary for waterfowl and other wildlife.

Mopping up in the marshy swampland would be next to impossible and the slick would also imperil the state’s 2.4-billion-dollar-a-year fisheries industry, which produces a significant portion of US seafood. Lieutenant Commander Cheri Ben-Iesau of the US Coast Guard told AFP that the initial burn-offs would be evaluated before any larger operations were attempted. As of 1800 GMT, no trial fires had been set, officials said. “Today they are just seeing this as a kind of trial fire to see if it even can be done,” she said. “I believe that they use an actual accelerant to start it. You can’t just throw a match in it and have it start.” Oil, at the rate of 42,000 gallons a day, is spewing from the riser pipe that connected the Deepwater Horizon platform to the wellhead before the rig sank last week after a deadly explosion that killed 11 workers.

BP, which leased the semi-submersible rig from Houston-based contractor Transocean, has been operating four robotic submarines some 1,500 meters (5,000 feet) down on the seabed to try and cap the well. They have failed so far to fully activate a giant 450-tonne valve, called a blowout preventer, that should have shut off the oil as soon as the disaster happened but only partially reduced the flow. As a back-up, engineers are frantically constructing a giant dome that could be placed over the leaks to trap the oil, allowing it to be pumped up to container ships on the surface. Another Transocean drilling rig is also on stand-by to drill two relief wells that could divert the oil flow to new pipes and storage vessels. But that would take up to three months and the dome is seen as a better interim bet even though engineers need two to four weeks to build it.

Tuesday’s oil burns could present their own environmental problems, sending huge plumes of toxic black smoke into the sky and leaving mucky residue in the sea. “We don’t want anyone downwind from the smoke,” said Ben-Iesau. “There are obviously dangers inherent in these sort of operations working offshore with a lot of big vessels.” The US government’s Environmental Protection Agency was to monitor air quality throughout the operations and officials gave assurances that the burning would be halted if safety standards were breached.

Coast Guard Rear Admiral Mary Landry, who is leading the government’s response to the disaster, warned on Tuesday that if BP fails to secure the well it could end up being “one of the most significant oil spills in US history.” The US government has promised a full investigation into the explosion that sank the platform and pledged to do all it can to stave off an environmental disaster. The spill also threatens to whip up a new political squall at a critical moment for a Democratic climate bill. President Barack Obama dismayed some supporters and environmental groups when he announced in March that his administration would explore lifting bans on offshore drilling in certain waters in a wider overhaul of energy policy. But assurances by the oil industry that new exploration is environmentally safe are now drawing new scrutiny.

The Deepwater Horizon rig went down last Thursday 130 miles southeast of New Orleans, still blazing two days after the blast that killed 11 workers as it dramatically sank into the sea. The widow of one of the dead has filed a lawsuit accusing the companies that operated the rig — BP, Transocean and US oil services behemoth Halliburton — of negligence. The accident has not disrupted offshore gulf oil production, which accounts for more than a quarter of the US energy supply.

‘IN SITU’ BURNING

http://www.fire.nist.gov/bfrlpubs/fire01/art076.html

http://www.fire.nist.gov/bfrlpubs/fire94/art088.html

http://www.fire.nist.gov/bfrlpubs/fire99/art009.html

http://blog.al.com/live/2010/04/burning_should_have_started_a.html

Burning should have started a week ago, says former NOAA official

by Ben Raines / April 29, 2010

Federal officials should have started burning oil off the surface of the Gulf last week, almost as soon as the spill happened, said the former oil spill response coordinator for the National Oceanic and Atmospheric Administration. Ron Gouget, who also managed Louisiana’s oil response team for a time, said federal officials missed a narrow window of opportunity to gain control of the spill by burning last week, before the spill spread hundreds of miles across the Gulf, and before winds began blowing toward shore.

He also said the heavy use of dispersants instead of burning the oil has likely knocked so much oil into the water column that portions of the Gulf may be on the threshold of becoming toxic to marine life. Add in the oil spreading into the water as it rises from the seafloor, and Gouget said he expected officials would have to begin limiting the use of the dispersants.

Gouget was part of the group that created the 1994 In-Situ Burn pre-approval plan that was designed to allow federal responders to begin burning oil as soon as a major spill occurred. “They had pre-approval. The whole reason the plan was created was so we could pull the trigger right away instead of waiting ten days to get permission,” Gouget said. “If you read the pre-approval plan, it speaks about Grand Isle, where the spill is. When the wind is blowing offshore out of the north, you have preapproval to burn in that region. If the wind is coming onshore, like it is now, you can’t burn at Grand Isle. They waited to do the test burn until the wind started coming onshore.”

Asked why officials waited for a week before conducting even a test burn, Gouget said, “Good question. Maybe complacency was the biggest issue. They probably didn’t have the materials on hand to conduct the burn, which is unconscionable.” He said the NOAA officials involved at the Unified Command Center in Louisiana know how to respond to spills, and know burning should have started as soon as possible after the initial release was detected. Gouget said they may have been overruled. “It may have been a political issue. The burn would make a big big plume and lots of soot. Like Valdez, the decisions to get the resources mobilized may not have occurred until it was too late,” Gouget said. “This whole thing has been a daily strip tease. At first they thought it was just the diesel, then they said the well wasn’t leaking. It’s unfortunate they didn’t get the burning going right away. They could have gotten 90 percent of the oil before it spread.”

Gouget said portions of the oil will still burn, especially the stuff bubbling up from the broken well. “I keep reading that burning will only get a small portion of the oil. Not true. This one is a continuing release,” Gouget said, with lots of “bright, fresh oil” that should burn fairly easily. “The bottom line, the limiting factor on burning is can you get it to burn. If it gets too thin, like a sheen, it won’t burn because you don’t have a fuel,” Gouget said. “Generally, it’s got to be thick enough, and it can’t be too weathered. This stuff is weathering immediately coming out of the pipe, losing the volatiles that burn most easily. They’ve got to get to it right away.”

Gouget said officials could still make a big dent in the amount of oil that will hit seashores over the next several months by burning. “If they set up multiple boat/fire boom sets & begin a ‘bucket brigade’ grabbing fresh oil, they can set up a production system to remove huge amounts,” Gouget said. “They’ve got to ramp up the burn program. It’s one of the most important tools they have to limit the damage.”

DRILL BABY DRILL

http://www.iosc.org/papers/01365.pdf

http://dotearth.blogs.nytimes.com/2010/04/28/spill-response-burn-baby-burn/

Spill Response: Burn Baby Burn

by Andrew C. Revkin / April 28, 2010

As federal officials prepare to test whether they can ignite a patch of the oil slick spreading from the seafloor wreckage of the Gulf of Mexico well, seasoned specialists say the logic in pursuing this option is clear and well established by decades of testing. One of the biggest such tests was undertaken off Newfoundland in 1993. Called the Newfoundland Offshore Burn Experiment, the joint Canadian and American project concluded that combustion consumed most of the more problematic compounds and the levels of harmful compounds in smoke were below danger thresholds outside 150 yards of so of the fire zone. The water beneath the burn area showed no detectable levels of harmful compounds.

I spoke this morning with David F. Dickins about burning spilled oil. He’s an environmental engineer who’s a veteran of decades of spill cleanups and studies. I first interviewed him for our “Big Melt” series on the implications of the growing human push into the warming Arctic in search of oil and gas and shipping routes. (He’s done tests of oil cleanup methods that may be needed in Arctic waters — and sea ice — someday.) He’s very bullish on burning where possible:

“I really believe that if there’s any possibility of burning the oil on the surface that should absolutely be carried out and attempted. There are huge net environmental benefits compared to letting it stay on the surface or hit the coast. There’s lots of evidence that there are no human health risks. After burning, there are fewer carcinogens and toxics than in the actual original oil. You really have a chance to remove 70, 80 or 90 percent of the oil. No other technique is going to take that much oil out of the environment.”

Nancy Rabalais, who studies pollution impacts on coastal ecosystems and led a study of oil impacts for the National Academy of Sciences, deferred on weighing the wisdom of burning, but said that if the oil crosses the 23 remaining miles of sea and soaks the fragile coastline, substantial impacts are inevitable. “If this hits shore, with all the sea-grass beds and marshes, it will be a mess,” she told me this morning.”

Here’s the Newfoundland project summary:

“A group of 25 agencies from Canada and the United States conducted a major offshore burn experiment near Newfoundland, Canada. Two lots of oil, about 50 cubic meters (50 tons) each, were released into a fireproof boom. Each burn lasted over an hour and was monitored for emissions and physical parameters. Over 200 sensors or samplers were employed to yield data on over 2000 parameters or substances. The operation was extensive; more than 20 vessels, 7 aircraft and 230 people were involved in the operation at sea.

The quantitative analytical data show that the emissions from this in-situ oil fire were less than expected. All compounds and parameters measured more than about 150 meters from the fire were below occupational health exposure levels; very little was detected beyond 500 meters. Pollutants were found to be at lower values in the Newfoundland offshore burn than they were in previous pan tests.

Polyaromatic hydrocarbons (PAHs) were found to be lower in the soot than in the starting oil and were consumed by the fire to a large degree. Particulates in the air were measured by several means and found to be of concern only up to 150 meters downwind at sea level. Combustion gases including carbon dioxide, sulphur dioxide, and carbon monoxide did not reach levels of concern. Volatile organic compounds (VOCs) were abundant, however their concentrations were less than emitted from the nonburning spill.

Over 50 compounds were quantified, several at levels of concern up to 150 meters downwind. Water under the burns was analyzed; no compounds of concern could be found at the detection level of the methods employed. Toxicity tests performed on this water did not show any adverse effect. The burn residue was analyzed for the same compounds as the air samples. Overall, indications from these burn trials are that 150 meters or farther from the burn source emissions from in-situ burning are lower than

health criteria levels.”

BOOM or BUST

http://www.treehugger.com/files/2010/05/booms-go-bust-bp-oil-barrier-wash-ashore-fail-crude-video.php

BP’s Oil Barriers Wash Ashore, Fail to Keep Out Crude

by Brian Merchant / 05.10.10

Yesterday, as we discovered that oil had made landfall in the mainland of Louisiana, we discovered another disturbing trend–that a bevy of booms, set up to block the fragile marshland from oil contact, had washed up on shores. This of course renders them useless. Reports of boom washing ashore in the stormy weather that’s been hitting the Gulf over the last few days haven’t been rare. But considering that this is one of BP’s primary prevention techniques, one of the methods it’s invested most in, their fallibility needs to be made known. It needs to be said that they are, in the words of Rick Steiner, conservation scientist and oil spill expert, “an exercise in futility.”

[youtube=http://www.youtube.com/watch?v=ihxcIV0z8jY]

And that’s in the best case scenario, when the booms stay put that they collect only a small fraction of the oil in the water. Just half an hour later, we came across huge stretches where boom had washed ashore entirely — and this happens with regularity up and down the coastline its intended to protect. Steiner says he’s glad that BP is trying. But the fact is, large swaths of oil are flowing past and under the booms, even when they haven’t been blown ashore.

2. SEND UNDERWATER ROBOTS

http://www.guardian.co.uk/environment/2010/apr/26/deepwater-horizon-spill-underwater-robots

Underwater robots trying to seal well

by Suzanne Goldenberg / 26 April 2010

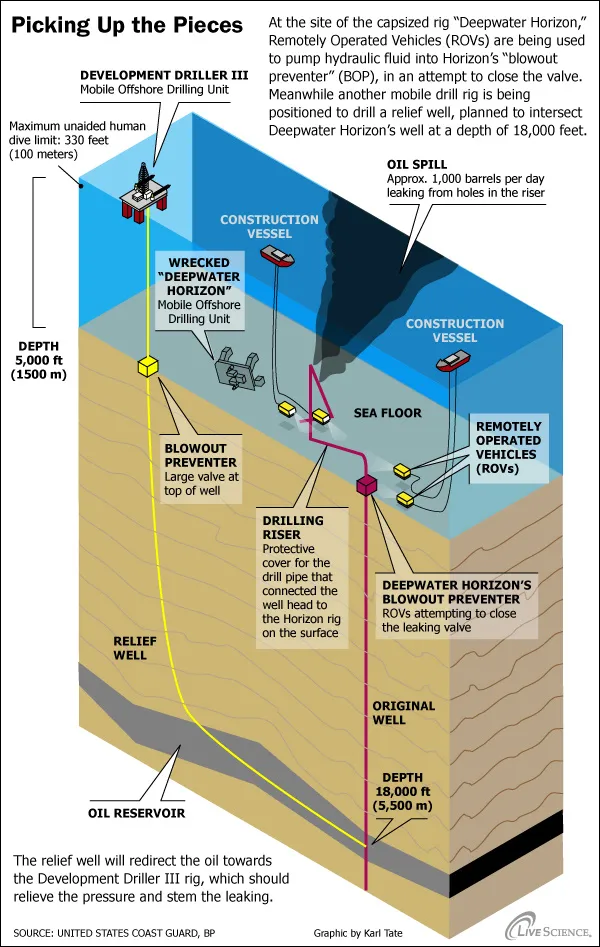

Underwater robots dived to the ocean floor yesterday in a new effort to staunch the 42,000 gallons of oil a day being pumped into the Gulf of Mexico in America’s worst offshore oil rig spill in 40 years. The robots will attempt to activate a blowout preventer, a 450-tonne valve on the ocean floor that offers the only timely option for stemming the flow. With the oil now coating 1,800 square miles of water, BP officials acknowledge it could take months to entirely contain two separate leaks from the wrecked oil rig. The US coastguard discovered the leaks on Saturday, two days after the Deepwater Horizon oil rig leased by BP sank off the coast of Louisiana. The rig was destroyed in an explosion last Tuesday, with 11 workers missing and presumed dead.

What initially seemed a manageable spill is now rated by the US coastguard as a serious environmental problem, with 1,000 barrels of oil a day being pumped into the Gulf of Mexico, an area rich with dolphins, whales and other marine life. Three sperm whales have been sighted in the area of the slick, officials said yesterday. The spill, which occurred just as senators were preparing to roll out energy and climate proposals, has deepened debate about America’s energy policies. In an effort to win support for the proposals, Barack Obama had come out in favour of more oil and gas drilling in the Gulf of Mexico.

High winds and big waves forced clean-up vessels, which have been trying to skim the oil from the surface of the water before it washes up on shore, to remain in port at the weekend. But Mary Landry, the coast guard commander, insisted the four states that lie in the path of the slick would have ample warning to protect fragile wetlands. Forecasts suggest the oil will make landfall on Thursday. The plan put into operation yesterday called for four underwater robots to dive 1,500 metres (5,000 ft) below the surface of the water to try to activate the gargantuan system of pipes and valves that sits next to the well on the ocean floor. BP said it was the first time such an operation had been mounted at this depth. “It is a slow process,” said Ron Rybarczyk, a spokesman at the command centre in Louisiana. “If you can visualise it, it’s like robotic arms doing something outside the space station. It is operating something with a mechanical claw on it that grasps things and turns things and adjusts equipment way down at the floor of the ocean.”

[youtube=http://www.youtube.com/watch?v=CH4I1a5vg3w]

BP also admits that the robots may not be successful. Doug Suttles, the chief operating officer of BP’s exploration unit, said activating the blowout preventer was a highly complex task – in part because it remains unclear whether the valve is working. The valve should have stopped the leak at the outset. “The issue we have is that we don’t know the condition inside that blowout valve,” he said. The laborious effort is by far the quickest means available for capping the leak.

Another option being pursued would be to lower a giant, upside-down funnel to the ocean floor, which would collect the escaping oil and divert it to a barge or a pipeline. That too would be a first – the method has only been deployed in shallow waters – and it would take time. Rybarczyk noted the device would have to be custom-built, though he did not give an estimate of how long that would take.

BP is also pursuing a more traditional fix, which would involve drilling relief wells nearby. Suttles said the first rig was due to arrive in the Gulf last night. The last spill from an oil rig in the Gulf of Mexico of similar magnitude took more than 10 months to contain, said Dagmar Schmidt Etkin, president of Environmental Research Consulting. But that was more than 40 years ago, and technology has advanced since then.

But she warned cleaning up after this accident would also prove challenging, especially if there continue to be stormy seas. Collecting such thin surface deposits is an inefficient process. “Even under the best circumstances you might get 10%-25% at most and that is when the weather is co-operative,” she said. “That is really pushing it.” As of yesterday morning, the crews have retrieved about 1,152 barrels of an oil-and-water mix, BP said.

3. BUILD a CONTAINMENT DOME

http://www.redorbit.com/news/science/1856257/engineers_rush_to_contain_us_oil_spill/index.html

Engineers Rush To Contain US Oil Spill / 27 April 2010

Just in case robotic submarines are not able to plug up an oil leak on a sunken rig in the Gulf of Mexico, engineers rushed Tuesday to build a giant containment dome to keep the spill quarantined. British oil company BP is operating four robotic submarines almost a mile undersea to try to activate a blowout preventer that should cap the oil well. But so far, after two days of efforts, they have not been able to accomplish that goal. The dome may be the best effort to keep the leak contained and avoid the threat of an environmental disaster from the slick that is developing off the coast of Louisiana. “It’s a dome that would be placed over the leak and instead of the oil leaking into the water column it would leak into this dome structure,” said US coast guard spokesman Prentice Danner. “They started working on the fabrication of this dome structure fairly recently and its estimated it will take two to four weeks to build,” he told AFP.

[youtube=http://www.youtube.com/watch?v=t8acPbITk0c]

The spill has created a massive leak that can be seen from space and, if the winds change, could threaten the fragile wetlands of Louisiana that are home to rare water birds and other wildlife. The threat is real and could affect the area within days. BP has sent an armada of skimmers, tugs, barges, and recovery boats to clean up the spill. More than 29,000 gallons of chemical product was dumped into the sea to disperse the oil as well. Transocean was sending a special rig to arrive late Tuesday to begin drilling two relief wells to cut off the flow of oil. BP cautioned that the relief wells would take up to three months to drill and with oil spewing out at 42,000 gallons a day, the dome would be the best bet to contain the oil. The dome would gather the oil and allow workers to pump it out of the dome. “If you could picture a half dome on top of the leak and the oil collects inside of this dome and is pumped out from there, that is the idea behind it,” said Danner. The dimensions of the dome are still being worked out, but officials said it would be similar to welded steel containment structures called cofferdams that are already used in oil rig construction.

1st ATTEMPT CLOGGED by ICE CRYSTALS

http://articles.latimes.com/2010/may/10/nation/la-na-oil-spill-20100510

BP looks for new plan to stop leak

by Richard Fausset, Julie Cart & Alana Semuels / 5.10.2010

After failing in their attempt to funnel the oil leaking under the Gulf of Mexico with a 100-ton box, BP officials on Sunday were considering deploying a smaller container that might be less prone to clogging. Capping the leak with a smaller box would ensure the oil and seawater mixture inside was warm enough to prevent the formation of slush that last week clogged the larger container, UC Santa Barbara geochemist David Valentine said. Gas mixing with cold water near the sea floor can form a matrix that is similar to crystal.

The plan was for the oil-and-water mixture to flow from the containment box through a pipe to the ocean’s surface, where it would be collected inside waiting tankers. BP officials had warned that the procedure had never been attempted so deep in the ocean. The smaller box, which could be deployed in a few days, is one of several options BP is considering, company spokesman Tom Mueller said. Another is a “hot tap,” in which a hole would be drilled into the existing broken pipe through which the oil could be drawn out. Robotic submarines would install a connector between the old pipe and the new. BP also is considering a “junk shot” option, Mueller said. That would involve injecting solid rubbery and fibrous material into the broken mechanism at the well head to stop it up. The temporary clog would give engineers time to use heavy fluids and cement to create a more permanent barrier. The drilling of a relief well, which could take three months, was continuing.

Meanwhile, Louisiana state authorities on Sunday extended a no-fishing zone farther west, to Atchafalaya Bay, as the forked oil plume menaced the state’s south and east shores. A state of emergency was declared in Lafourche Parish, west of the Mississippi River, and the slick edged into Chandeleur and Breton sounds, east of New Orleans. Authorities said they had laid about 190 miles of boom and were employing 277 vessels, 10,000 personnel and an armada of volunteers, many of them fishermen fighting to save their livelihoods. Weather and wind predictions show that the westward-moving oil slick will probably hit numerous ecologically sensitive shores near the mouth of the Mississippi River and around the marshes of southeastern Louisiana.

4. ‘JUNK SHOT’

http://www.guardian.co.uk/environment/blog/2010/may/10/deepwater-horizon-oil-spill-oil-spills

Plugging the Leak with Golf Balls & ‘Things Like That’

BP engineers may try to bung up the Deepwater Horizon leak by pumping debris such as bits of tyres and golf balls into the well. It’s a long shot known as a ‘junk shot’, but it might just work Since the Deepwater Horizon explosion two weeks ago, it has been hard not to view as primitive the efforts to contain the oil and prevent more of it leaking. Whether it is the containment booms drafted in to prevent the oil washing ashore or early efforts to set the oil on fire, or even the attempts to funnel the leaking oil via giant sunken towers, the somewhat low-tech containment efforts starkly contrast with the often hi-tech methods usually witnessed in deep-sea drilling.

The latest BP plan being weighed up is similarly low-tech. Engineers may try to plug the well by pumping debris into it at high pressure, a method known as a “junk shot”. “They are actually going to take a bunch of debris – some shredded up tyres, golf balls and things like that – and under very high pressure shoot it into the preventer itself and see if they can clog it up to stop the leak,” the US Coast Board Admiral Thad Allen told CBS News yesterday. Tyres, golf balls, and “things like that” do not immediately inspire confidence, However Dr Simon Boxall, oceanographer at the National Oceanography centre in Southampton, Hampshire, said the unique conditions of the Deepwater Horizon spill – there has never been an oil leak at this depth before – mean all traditional methods “go out of the window”.

There have been blow outs in shallow water, but with those you’re looking at 100-metre-deep tops, where you can get divers down and you can get equipment down,” he said. “It’s nothing compared to doing it 1,500m [5,000ft] down – this goes beyond all our technological knowhow and experience.”. Boxall said a junk shot has been tried before, although he was only aware of one incident, which took place at a much shallower depth. “We’re working in completely new territory, but the idea is not quite as daft as it sounds,” he said. “Bear in mind the pressures at these depths are phenomenal, so what seems like an odd thing to bung a hole with at the surface can actually work quite well. Golf balls seem really quite hard but actually they’re quite soft. “Certainly if you add a tonne of pressure per square inch to a golf ball then it starts to give. So I guess what they’re looking to do is use these things that are slightly plastic in their feel to bung into a hole which will help bung it up.”

The main problem for engineers is how to get the debris into the well almost a mile beneath the surface. The plan is to block the well beneath the semi-operational cut-off valves – at the moment, the well is partly shut off, restricting the oil flow – without making the spill worse. “They’re planning to sort of try and insert them somehow magically before the cut off valve, but that doesn’t quite make sense,” Boxall said. “All these things you can imagine are perfectly feasible on land if you had whatever technology was available to bung them in the hole. “But when you’re looking at some mechanism to fire them into a hole when you’re a mile down in seawater, I can’t imagine what they would use, unless they’re using compressed air – but that is difficult at those depths anyway because the pressures are so great.” He added: “There are one or two engineers out there who seem to be thinking: ‘This is ok as long as we don’t cause more damage than we solve.'” BP’s ultimate solution to the leak is to drill a relief well, but that could take up to three months before that is completed. In the meantime, they will continue to try and position a cofferdam over one of the leaks today.

Underwater nuclear test, 1958

5. NUKE IT (LIKE the RUSSIANS DO)

http://www.kp.ru/daily/24482/640124/

http://www.themoscowtimes.com/news/article/us-oil-spill-sets-off-alarm-bells-in-russia/405405.html

http://trueslant.com/juliaioffe/2010/05/04/nuke-that-slick/

Nuke that slick

by Julia Ioffe / May 4 2010

As BP prepares to lower a four-story, 70-ton dome over the oil gusher under the Gulf of Mexico, the Russians — the world’s biggest oil producers — have some advice for their American counterparts: nuke it.

Komsomoloskaya Pravda, the best-selling Russian daily, reports that in Soviet times such leaks were plugged with controlled nuclear blasts underground. The idea is simple, KP writes: “the underground explosion moves the rock, presses on it, and, in essence, squeezes the well’s channel.”

Yes! It’s so simple, in fact, that the Soviet Union, a major oil exporter, used this method five times to deal with petrocalamities. The first happened in Uzbekistan, on September 30, 1966 with a blast 1.5 times the strength of the Hiroshima bomb and at a depth of 1.5 kilometers. KP also notes that subterranean nuclear blasts were used as much as 169 times in the Soviet Union to accomplish fairly mundane tasks like creating underground storage spaces for gas or building canals.

These kinds of surgical strikes to shut off underground leaks, however, were carried out only five times, with the last one occuring in 1979. And there was only one misfire, near Kharkov, Ukraine, where a nuclear blast was unable to stanch a gas leak. Happily, with a track record like that, “the chances of failure in the Gulf of Mexico are 20%,” KP writes. “The Americans could certainly risk it.”

vs. an UNCONTROLLED BURN

http://news.nationalgeographic.com/news/2010/04/100422-oil-rig-explosion-shows-risks/

http://online.wsj.com/article/SB10001424052748704423504575212031417936798.html

Leaking Oil Well Lacked Safeguard Device

by Russell Gold, Ben Casselman & Guy Chazan / 4.28.2010

The oil well spewing crude into the Gulf of Mexico didn’t have a remote-control shut-off switch used in two other major oil-producing nations as last-resort protection against underwater spills. The lack of the device, called an acoustic switch, could amplify concerns over the environmental impact of offshore drilling after the explosion and sinking of the Deepwater Horizon rig last week. The accident has led to one of the largest ever oil spills in U.S. water and the loss of 11 lives. On Wednesday federal investigators said the disaster is now releasing 5,000 barrels of oil a day into the Gulf, up from original estimates of 1,000 barrels a day.

U.S. regulators don’t mandate use of the remote-control device on offshore rigs, and the Deepwater Horizon, hired by oil giant BP PLC, didn’t have one. With the remote control, a crew can attempt to trigger an underwater valve that shuts down the well even if the oil rig itself is damaged or evacuated. The efficacy of the devices is unclear. Major offshore oil-well blowouts are rare, and it remained unclear Wednesday evening whether acoustic switches have ever been put to the test in a real-world accident. When wells do surge out of control, the primary shut-off systems almost always work. Remote control systems such as the acoustic switch, which have been tested in simulations, are intended as a last resort.

Nevertheless, regulators in two major oil-producing countries, Norway and Brazil, in effect require them. Norway has had acoustic triggers on almost every offshore rig since 1993. The U.S. considered requiring a remote-controlled shut-off mechanism several years ago, but drilling companies questioned its cost and effectiveness, according to the agency overseeing offshore drilling. The agency, the Interior Department’s Minerals Management Service, says it decided the remote device wasn’t needed because rigs had other back-up plans to cut off a well. The U.K., where BP is headquartered, doesn’t require the use of acoustic triggers.

On all offshore oil rigs, there is one main switch for cutting off the flow of oil by closing a valve located on the ocean floor. Many rigs also have automatic systems, such as a “dead man” switch as a backup that is supposed to close the valve if it senses a catastrophic failure aboard the rig. As a third line of defense, some rigs have the acoustic trigger: It’s a football-sized remote control that uses sound waves to communicate with the valve on the seabed floor and close it.

An acoustic trigger costs about $500,000, industry officials said. The Deepwater Horizon had a replacement cost of about $560 million, and BP says it is spending $6 million a day to battle the oil spill. On Wednesday, crews set fire to part of the oil spill in an attempt to limit environmental damage. Some major oil companies, including Royal Dutch Shell PLC and France’s Total SA, sometimes use the device even where regulators don’t call for it. Transocean Ltd., which owned and operated the Deepwater Horizon and the shut-off valve, declined to comment on why a remote-control device wasn’t installed on the rig or to speculate on whether such a device might have stopped the spill. A BP spokesman said the company wouldn’t speculate on whether a remote control would have made a difference.

Much still isn’t known about what caused the problems in Deepwater Horizon’s well, nearly a mile beneath the surface of the Gulf of Mexico. It went out of control, sending oil surging through pipes to the surface and causing a fire that ultimately sank the rig. Unmanned submarines that arrived hours after the explosion have been unable to activate the shut-off valve on the seabed, called a blowout preventer. BP says the Deepwater Horizon did have a “dead man” switch, which should have automatically closed the valve on the seabed in the event of a loss of power or communication from the rig. BP said it can’t explain why it didn’t shut off the well.

Transocean drillers aboard the rig at the time of the explosion, who should have been in a position to hit the main cutoff switch, are among the dead. It isn’t known if they were able to reach the button, which would have been located in the area where the fire is likely to have started. Another possibility is that one of them did push the button, but it didn’t work. Tony Hayward, BP’s CEO, said finding out why the blowout preventer didn’t shut down the well is the key question in the investigation. “This is the failsafe mechanism that clearly has failed,” Mr. Hayward said in an interview. Lars Herbst, regional director of the Minerals Management Service in the Gulf of Mexico, said investigators are focusing on why the blowout preventer failed.

Industry consultants and petroleum engineers said that an acoustic remote-control may have been able to stop the well, but too much is still unknown about the accident to say that with certainty. Rigs in Norway and Brazil are equipped with the remote-control devices, which can trigger the blowout preventers from a lifeboat in the event the electric cables connecting the valves to the drilling rig are damaged. While U.S. regulators have called the acoustic switches unreliable and prone, in the past, to cause unnecessary shut-downs, Inger Anda, a spokeswoman for Norway’s Petroleum Safety Authority, said the switches have a good track record in the North Sea. “It’s been seen as the most successful and effective option,” she said.

The manufacturers of the equipment, including Kongsberg Maritime AS, Sonardyne Ltd. and Nautronix PLC, say their equipment has improved significantly over the past decade. The Brazilian government began urging the use of the remote-control equipment in 2007, after an extensive overhaul of its safety rules following a fire aboard an oil platform killed 11 people, said Raphael Moura, head of safety division at Brazil’s National Petroleum Agency. “Our concern is both safety and the environment,” he said.

photo taken by a DOE contractor

Industry critics cite the lack of the remote control as a sign U.S. drilling policy has been too lax. “What we see, going back two decades, is an oil industry that has had way too much sway with federal regulations,” said Dan McLaughlin, a spokesman for Democratic Florida Sen. Bill Nelson. “We are seeing our worst nightmare coming true.” U.S. regulators have considered mandating the use of remote-control acoustic switches or other back-up equipment at least since 2000. After a drilling ship accidentally released oil, the Minerals Management Service issued a safety notice that said a back-up system is “an essential component of a deepwater drilling system.”

The industry argued against the acoustic systems. A 2001 report from the International Association of Drilling Contractors said “significant doubts remain in regard to the ability of this type of system to provide a reliable emergency back-up control system during an actual well flowing incident.” By 2003, U.S. regulators decided remote-controlled safeguards needed more study. A report commissioned by the Minerals Management Service said “acoustic systems are not recommended because they tend to be very costly.” A spokesman for the agency, Nicholas Pardi, said the decision not to require the device came, in part, after the agency took a survey that found most rigs already had back-up systems of some kind. Those systems include the unmanned submarines BP has been using to try to close the seabed valve.

BURN WHAT EXACTLY?

http://www.eurekalert.org/pub_releases/2009-07/ci-hit072409.php

http://www.livescience.com/environment/090316-oil-origin.html

The Chemistry of Life: Where Oil Comes From

by Michael Schirber / 16 March 2009

Oil, the lifeblood of U.S. transportation today, is thought to start with the remnants of tiny organisms that lived millions of years ago, but the exact chemical transformation is somewhat mysterious. New research is looking at the role played by microorganisms that live in the deep dark bowels of the Earth. A minority of scientists say otherwise, but most geologists think that the petroleum we pump from the ground (and later refine into gasoline and other fuels) comes predominantly from the fossils of marine life, such as algae and plankton. “There is a lot of evidence to support the biogenic origin,” said Everett Shock, a biogeochemist at Arizona State University. “Some of the petroleum molecules, for example, resemble the lipids found in bacterial cell membranes.”

Whereas most of the dead material in the ocean is recycled by bacteria, lipids are tough, fat-like molecules that “tend to be the least desirable to eat,” Shock said. They generally get passed up and fall to the seafloor, where they become buried under layers of sediment and eventually cooked into petroleum. Once the organic remains become entombed in rock, most scientists have assumed that biology ends and geology takes over. However, deep drilling expeditions in the past few decades have discovered bacteria living thousands of feet below the surface, at the same depths where petroleum is forming. “Are these microorganisms directly involved in the reactions that turn organic material into petroleum?” asked Shock. He is leading a research group funded by the National Science Foundation that aims to figure out what these deep-dwelling microbes may be living off of and what influence they may have on petroleum chemistry.

Oil battery

Even if some uncertainty remains over the exact chemical pathway to oil, the starting point is not in doubt. “The ultimate source of energy is the sun, and oil is just a ‘battery,'” said Barry Katz, a research scientist at Chevron. Plants and certain bacteria use sunlight to convert carbon dioxide into sugar. This stored chemical energy is passed along the food chain, and a few “crumbs” wind up getting buried underground. Once there, this organic material is transformed by heat and pressure into a complex mixture called kerogen. Depending on the initial ingredients and the geologic conditions, kerogen can produce either coal (a solid carbon-rich fuel derived mostly from woody plants) or hydrocarbons (a relatively hydrogen-rich substance that comes from algae and various lipid-containing plant parts).

Hydrocarbons are typically long chains of carbon and hydrogen atoms. The smaller hydrocarbon molecules (such as methane, propane and butane) are found in natural gas. The larger hydrocarbons (such as hexane and octane) make up petroleum. As was mentioned, certain types of kerogen will form and release hydrocarbons — typically when the temperature rises above 212 degrees Fahrenheit (100 degrees Celsius). “It’s a very inefficient process,” Katz said. “Less than 1 percent of the organic material growing in the ocean becomes hydrocarbons.” Even when oil does form, it does not always last. Some of it migrates up to the surface, where oil-eating microbes consume the better parts of it (creating so-called tar sands). To prevent this from happening, there needs to be a geologic formation that can trap the petroleum in a reservoir. “Charging” this oil battery can take anywhere from 1 million to 1 billion years, with most petroleum we use being around 100 million years old.

Energy drain

The chemically stored solar energy is whittled away by the long and intricate process of petroleum formation. “Petroleum in the ground is at a low energy state,” Shock told LiveScience. “It only becomes energetic when we bring it up to the surface and introduce it to an oxygen atmosphere.” The reduced energy potential of buried organic material begs the question: what are deep-dwelling microbes surviving on? “We don’t know what they do,” Shock said. “We just met them.” One possibility is that they are eating small organic byproducts that get expelled from the kerogen at the same time as the hydrocarbons. The other possibility is that these hearty bugs are actively helping to catalyze the reactions that create oil and siphoning off a bit of the remaining energy for themselves.

Simulating at high speed

Shock’s team plans to create petroleum in the lab to see if there is any aspect of the process that might support bacteria. This won’t be the first time that scientists have simulated natural petroleum formation. To speed up the cooking process, researchers generally turn the temperature up to several 100 degrees Celsius. “No one wants to wait around 10 million years for an experiment to finish,” Shock said. The assumption is that the same reactions occur at both high and low temperatures, but no one can say for sure that this is the case. “It’s rather remarkable that we are so dependent on oil, and yet we really don’t understand how it is made in all its gory details,” Shock said. Perhaps these subterranean microbes will help fill in the missing pieces.

A hard hat covered in oil that was found in Louisiana waters Monday.

Our company has the only world’s supply of recycled polyurethane powder that is consider the best oil-sorbent but no one has ever built the feedstock supply infrastructure until Mobius did so to apply the MPU as a green-replacement of the petro-chem derived glues (MDI’s) in engineered wood manufacturing.

The amazing oil-sorbent efficacy of PU, though well known, was never applied in any magnitude. We have an amazing sorbent solution but can’t get it to ground zero!

The product name is MPU – Micronized Polyurethane powder. PU has been proven to be the BEST synthetic oil-sorbent and we can have this material on the ground via container ship from our warehouse in 2 weeks and can provide a consistent flow of 1,000,000lbs every two-three weeks. PUhas a proven 5x+ greater the oil-sorption capacity than polypropylene.

We process the polyurethane so that is floats vs. sinks when it absorbs oil. It needs to be blow onto the oil surface or aerial dropped. The MPU-Oil-Cake FLOATS and can significantly enhance control-burns tactics as PU burns as hot as coal 18,000btu’s/lb and most importantly, while the oil burns the PU will soften but not melt, so it will stay afloat, unlike pp.

How do we get this material on the water now?! We need a direct remediation decision-making line to BP and the coast guard on the ground so we can do a test proof. With 7-10,000 calls into the hotline that channel is over-loaded.

Please help us get this highly efficacious oil-sorbent and burn-agent on the ground in the gulf.

Thansk you.

Brian

916.262.4016

brian.hennessy@mobiustechnologies.com